“Ethical Markets highly recommends this article on a radical advance in electrification.

~Hazel Henderson, Editor”

One potentially huge contributor to decarbonization of the economy could come from dramatic efficiency gains obtainable from digitally improving the power quality of electricity, as it is being generated, transmitted & being consumed. The enabling technology is emerging from developments in computing that is associated with the Internet of Things (IOT).

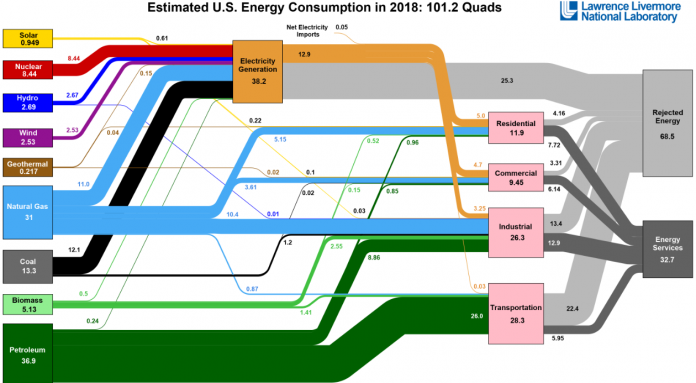

DOE estimates indicate that approximately 38.2 quads of electricity are produced, from all sources, but that 25.3 quads, or 66.2% is deemed “Rejected Energy”, so only 33.8% of generated electricity is actually being used. Within that 66% a distinction is recognized between “Losses” & “Waste”:

- Loss is non-recoverable, I2R losses that would occur unavoidably in a theoretically ideal electrical network.

- Waste is recoverable, because it is due to unsynchronized power & non intelligent distribution of electricity, which is potentially correctable.

The DOE does not quantify the proportions, but independently it has been estimated that as much as 50% of the Rejected Energy may be recoverable, so 50% of the 66%, perhaps 30-35% of the total generated, may be accessible to mitigation by waste-reducing technology. This constitutes a market of billions of dollars in potential savings which is being addressed by a huge Power Quality market competing to provide products & methodologies to mitigate waste due to distortions and inefficiencies. Despite these advancements and the scale of the industry offering solutions, data that would quantify the amount of waste actually mitigated is hard to find, perhaps because measurement and verification methods are inadequate, non-digital.

Suffice to say, a fully optimized Grid with zero waste that was able to add another 30-35% to the available 33%, would nearly double the capacity of available electricity. This might have the effect of flattening demand forecasts, or even render some existing capacity redundant. And if adoption of optimization solutions was rapid enough, sufficiently large curtailment could result in financial stranding of surplus generating assets, which in turn could impact the public conversation about use of fossil fuels for power generation, accelerate wind down of coal plants and increase awards to battery peaking over gas peakers.

The main focus of Digitial Electrification is reduction in the thermal waste produced by inefficiencies in power quality due to various distortions in the shape of the sinusoidal wave form.

What Digital Electrification is NOT

Digital Electrification is distinguishable from the “Digitization & Digitalization” broadly associated with “demand response” capabilities, and the many products and sub-disciplines instrumental to the goal of transitioning to a “smart grid”. The breadth of this far-reaching industry is captured in this infographic by ABB & Zpryme, showing 3 stages, dozens of goals in process, and a long list of topics & acronyms, the most familiar perhaps include:

- Smart meters (AMI – advanced metering infrastructure) to automate end user peak demand reductions, reduce inefficiencies and pass along cost savings.

- Demand Response Management Systems (DRMS), to coordinate load shifting

- Distributed Response Management Systems (DERMS), support integration of Distributed Energy Resources (DERs) & integration of intermittent generation from renewables, solar, wind & storage to support energy arbitrage, aggregation of batteries on site & in vehicles (V2G) into Virtual Power Plants (VPPs), and implement “non-wires alternatives” (NWAs).

- Supervisory Control & Data Acquisition (SCADA), big data management of circuit balancing,

- Outage Management Systems (OMS)

Digital Electrification is based on Software Defined Electricity (SDE)

3DFS is a small start up in North Carolina dedicated to development of SDE, which last received national level press coverage in a profile published in 2016 by Vox. Chris Doerfler, CEO of 3DFS, contends that waste due to poor power quality is fixable with 3DFS technology.

SDE is actually a term in use by other firms, such as vendors CUI & VPS, which essentially offer high end demand side management, reducing consumption by controlling equipment assets with equipment and sensors distributed throughout the equipment, managed through APIs, and can achieve some efficiencies in usage through peak shaving.

3DFS is different from these companies because its technology manages the way electricity moves through a power grid, not where it moves. 3DFS instead is installed non-intrusively in parallel directly to the electrical network panel, and is able to monitor & correct the flow of electricity itself, recognizing any non-sinusoidal waveform, line impedance or reactive power from unbalanced phases, that is producing waste heat.

Electricity is currently not precisely measured, rather, existing technologies use estimations calculated using Root Mean Square (RMS). RMS values are averages of electrical parameters based on less than 1% of real values. Most “smart” meters are inexpensive & low fidelity because they do not have digital processors. RMS sampling acquire 6000 values every second, 100 data points per sinewave at 60hz, or roughly one data point every .17 milliseconds which leaves as much as 99% unsampled. This data quality is not high enough to be usable for correcting distortions. Based only on this imprecise data, existing technologies typically compensate using transformers, capacitors and power switching technology. But in order to correct electricity more efficiently, continuous subcycle information is needed.

3DFS data acquisition oversamples the electricity, acquiring 26 separate electrical parameters (current, voltage, phase angle, power factor, harmonics, reactive power) at MHz frequencies and 24 bit resolution, 8192 times per cycle. This provides an exact digital replica of the analog signal within a few nanoseconds, with no errors, no rounding, and zero noise, rendering RMS values obsolete, because it acquires the data nearly 50,000 times faster than any technology that relies on RMS values.